ERP For the Manufacturing Industry

Table Of Content

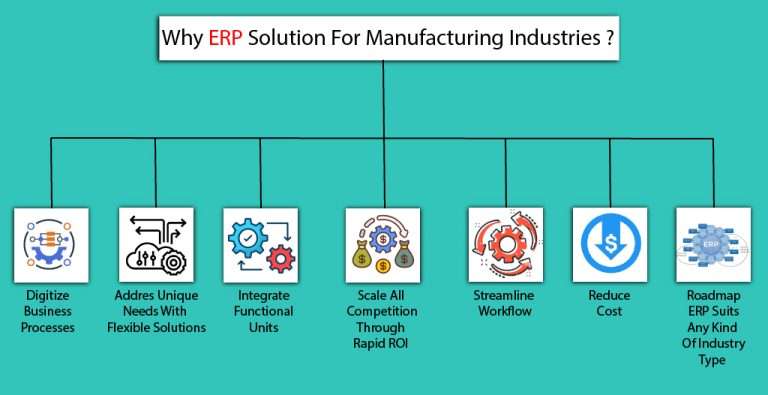

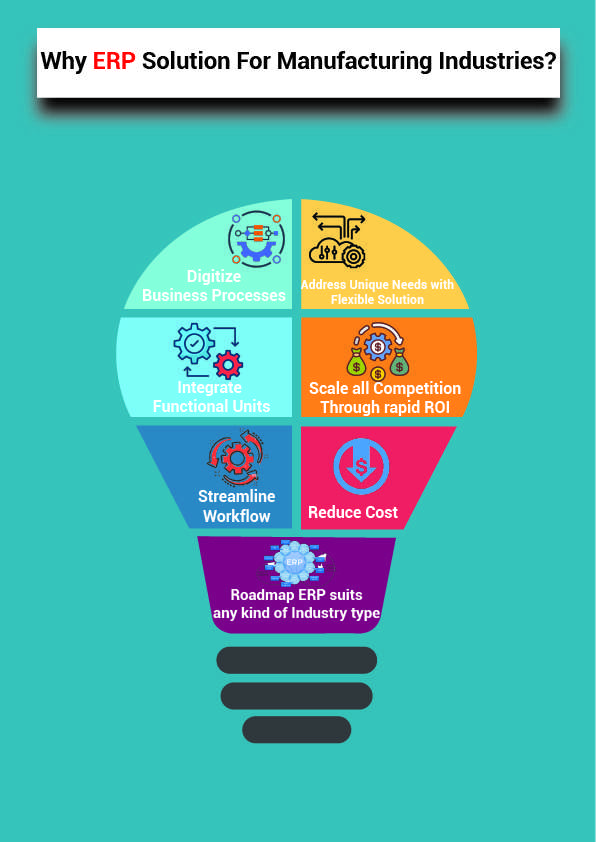

In today’s fast-paced manufacturing industry, staying competitive requires efficient processes, streamlined operations, and seamless coordination across various departments. ERP (Enterprise Resource Planning) systems have become an effective response to these problems.

In this article, we’ll look at the ERP concept and how it’s revolutionizing the manufacturing industry. From its benefits to its implementation considerations, we will delve into the essential aspects of ERP for the manufacturing sector.

The Manufacturing Industry: What Does It Mean?

The manufacturing industry includes the manufacturing of tangible goods through a variety of procedures, including the sourcing of raw materials, assembly, and distribution. It covers a wide range of industries, including textiles, food & beverage, electronics, automotive, and aerospace. The manufacturing sector plays an important role in the expansion of the global economy, the creation of new jobs, and the advancement of technology.

One of the main factors behind economic growth is the industrial sector. It stimulates investment, trade, and productivity, leading to increased GDP and prosperity. Manufacturing activities create value-added products that meet consumer demand and fuel domestic and international trade.

This industry generates employment opportunities. A trained workforce is necessary for manufacturing facilities, which employ a wide range of people from engineers and technicians to assembly line workers. These occupations frequently provide consistent remuneration and potential for professional advancement, helping the overall development of society.

The manufacturing industry also fuels technological advancement and innovation. In this industry, research and development activities result in the development of new products, higher production efficiency, and better production methods. Manufacturing technology advancements have far-reaching impacts, revolutionising industries and influencing the future of several industries, including the automobile, electronics, and pharmaceutical industries.

Overall, the manufacturing sector contributes significantly to economic growth, employment creation, and technical advancement, making it a fundamental pillar of modern society.

How ERP Systems Can Help the in Manufacturing Operations:

ERP plays an important role in the manufacturing industry by centralizing data, streamlining operations, and promoting departmental collaboration. Removing silos and offering a comprehensive overview of the entire production process, enables businesses to decide wisely, optimize utilisation of resources, and increase operational effectiveness.

Firstly, an ERP system provides integrated management of various functions within a manufacturing organization. It enables smooth cooperation between multiple departments, including manufacturing, inventory, finance, and human resources, it enables smooth cooperation. This integration facilitates real-time data sharing, eliminates redundant tasks, and improves communication, leading to smoother operations and reduced lead times.

Secondly, ERP systems offer comprehensive inventory management capabilities. They enable manufacturers to track raw materials, work-in-progress, and finished goods, ensuring optimal inventory levels and minimizing stockouts or excess inventory. By providing accurate and timely information, ERP systems enhance supply chain visibility, enabling better planning, procurement, and order fulfillment.

Thirdly, an ERP system enables effective production planning and scheduling. It helps manufacturers create production schedules based on demand forecasts, capacity constraints, and resource availability. This optimizes resource utilization, reduces downtime, and improves on-time delivery performance.

Also, ERP systems provide robust data analytics and reporting capabilities. Manufacturers can analyze key performance indicators (KPIs) related to production, quality, costs, and customer satisfaction. This data-driven insight empowers informed decision-making and supports continuous improvement initiatives.

Overall, ERP Systems can revolutionize manufacturing operations by integrating functions, optimizing inventory management, improving production planning, and providing valuable analytics. It enhances operational efficiency, reduces costs, and drives overall competitiveness in the dynamic manufacturing industry.

The Key Features of Effective ERP Systems for the Manufacturers:

ERP systems for the manufacturing industry typically include components such as:

Helps in tracking and managing raw materials, work-in-progress, and finished goods inventory.

Ensures the timely availability of materials based on production demand.

Co-ordinating procurement, supplier management, and logistics for material flow.

Optimizing production schedules, capacity utilization, and resource allocation.

Implementing quality checks, inspections, and corrective actions to maintain product standards.

Systematic approach of acquiring, operating, and disposing of assets throughout their life-cycle.

Benefits of Implementing ERP Systems in the Manufacturing Industry:

There are several benefits of using ERP (Enterprise Resource Planning) systems in the manufacturing sector, and these advantages can significantly increase operational effectiveness and productivity. Some major advantages are:

- ERP Systems help in enhancing Inventory Management

ERP enables real-time visibility into inventory levels, ensuring accurate tracking and efficient utilization of materials. By minimizing stock-outs and optimizing inventory levels, manufacturers can reduce costs, improve order fulfillment, and enhance customer satisfaction.

- It creates efficient Production Planning

With ERP, manufacturers can create accurate production schedules based on demand forecasts, resource availability, and delivery commitments. This leads to optimized production processes, reduced lead times, and increased on-time delivery performance.

- It facilitates streamlined Supply Chain Management

ERP facilitates seamless integration with suppliers, distributors, and other external stakeholders. It enables end-to-end visibility of the supply chain, ensuring smooth material flow, timely deliveries, and effective demand management.

- ERP System Improves Quality Control

By implementing quality control modules within the ERP system, manufacturers can enforce stringent quality standards, track non-conformities, and initiate corrective actions. This ensures consistent product quality, reduces rework, and minimizes customer complaints.

- It generates Real-Time Data Insights

ERP systems generate real-time reports and analytics, providing manufacturers with valuable insights into key performance indicators (KPIs). Businesses can make data-driven decisions and discover areas for improvement by keeping an eye on measures like production efficiency, inventory turnover, and client demand.

When choosing an ERP software solution for the Manufacturing Industry, consider these factors:

The manufacturing industry operates in a complex and fast-paced environment, where efficiency, productivity, and streamlined processes are vital. An ERP software solution can significantly enhance your operations by integrating various business functions into a centralized system. When selecting an ERP software solution for the manufacturing industry, there are several critical factors to consider. Let’s explore each and every aspect in detail one by one.

- ERP Solutions Scalability and Flexibility

One of the primary considerations when choosing an ERP software solution is scalability. Manufacturers need a system that can adapt to their evolving business requirements, accommodating growth and expansion. It is crucial to assess whether the ERP solution can handle an increasing volume of data, users, and transactions without compromising performance.

Look for a software solution that offers flexible modules and customization options to adapt to your evolving needs. This way, you can avoid the hassle of switching to a new system in the future.

- Determine Functionality of Specific Industries:

The size and complexity of the business will determine the level of functionality that is required from the ERP software solution. Manufacturing processes are diverse, and each industry has unique requirements. Look for an ERP software solution that offers industry-specific functionality tailored to your manufacturing sector. Whether it’s discrete manufacturing, process manufacturing, or mixed-mode manufacturing, the ERP system should align with your specific operational needs.

- Allow Integration Capabilities for real-time data synchronisation:

Efficient data flow across different departments and systems is vital for smooth operations. Ensure that the ERP software integrates seamlessly with existing systems such as CRM, inventory management, supply chain, and shop floor control. Integration capabilities allow for real-time data synchronization and provide a holistic view of the business.

- User-Friendliness and Training

Your staff may experience a big change when you adopt a new ERP system. To ensure a smooth transition and user adoption, prioritize user-friendliness when selecting an ERP software solution. The system should have an intuitive interface, easy navigation, and provide comprehensive training and support to enable employees to leverage their full potential.

- Data Security and Compliance

Data security is a critical concern for any organization, and the manufacturing industry is no exception. When evaluating ERP solutions, pay close attention to the system’s security features, including role-based access controls, data encryption, and disaster recovery mechanisms. Ensure that the ERP software complies with relevant industry regulations and data protection standards.

- Mobile Accessibility

With the increasing trend of remote work and the need for real-time information, mobile accessibility has become a significant factor in ERP software selection. Consider an ERP solution that offers mobile compatibility, enabling users to access critical data and perform essential tasks from their mobile devices, regardless of their location.

Conclusion

ERP has revolutionized the manufacturing industry by providing a comprehensive solution for managing complex processes and driving operational efficiency. From inventory management to production planning and supply chain optimization, ERP systems offer a wide range of benefits. By embracing ERP and following best practices during implementation, manufacturers can enhance productivity, reduce costs, and stay competitive in an ever-evolving market.

When choosing an ERP software solution for the manufacturing industry, remember to consider scalability, industry-specific functionality, integration capability, real-time analytics, and a user-friendly interface. Taking these factors into account will help you make an informed decision and select a solution that aligns with your business goals.